SURFACE TREATIMENT

표면처리

Shinyang Plating

- information

- Overview

- Key Products

- Facilities

Specializing in electroless nickel plating,

Shinyang Plating, with its technological

personnel equipped with extensive experiences

and expertise, has secured Korea’s leading

companies as customers. While leading quality

standardization for precision parts and

mechanical parts, such as load shell, hydraulic

valve, various tools and instruments, and

powder metallurgy, Shinyang Plating is striving

to expand the development of general nickel

plating and deposition plating technologies

through its R&D division.

[information]

- Address

- 2nd floor, Namdong Indus Tower, Lot 11, Block 21, Namdong Industrial Complex, 59, Eunbong-ro, Namdong-gu, Incheon Metropolitan City, Korea

- Tel

- +82-32-819-4624

- Fax

- +82-32-819-4625

- Website

- http://www.hhpp.co.kr/

Products

Electroless nickel plating

Certifications

ISO 9001, Venture Company

Production Facilities

Ultrasonic cleaner, plating bath, drying furnace, heat treatment furnace

[History]

- 2005 Hwanghae P&P established

- 2007 Changed trade name to Shinyang Plating

- 2009 Changed to Shinyang Plating Co., Ltd.

- 2011 Obtained Venture Company certification

- 2013 Relocated to current address

- 2018 Obtained certification for R&D division

- information

- Overview

- Key Products

- Facilities

[Business Overview and Key Products]

- Electroless nickel plating enables precision work depending on the purpose and material as it produces very uniform and

strong plating layers.

1) Reflecting Plating in Design: Pre-examination of material, hardness, and roughness, etc, reflection at design and assembly

2) Selecting Plating Type: Considering plating type, purpose, characteristics, and strengths/weaknesses

3) Deciding Plating Quality: Deciding plating quality, such as plating thickness, by considering product use and

characteristics

[Features and Strengths]

- Bending (high-ductility plating method to prevent cracking of plating layer during test)

- Double-plating method requiring high adhesion

- Plating method for dentistry tools

- Plating method ensuring high corrosion resistance to withstand salt spray test for 72 hour

- information

- Overview

- Key Products

- Facilities

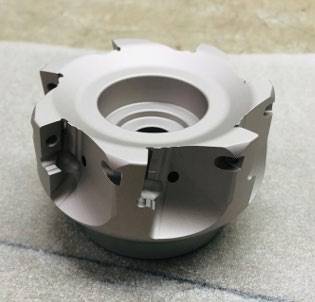

[Key Products]

-

Electroless Nickel Plating

Electroless Nickel Plating

-

Electroless Nickel Plating

Electroless Nickel Plating

-

Electroless Nickel Plating

Electroless Nickel Plating

-

Electroless Nickel Plating

Electroless Nickel Plating

-

Electroless Nickel Plating

Electroless Nickel Plating

- information

- Overview

- Key Products

- Facilities

[Production Facilities]

-

Pre-treatment

Pre-treatment

-

Plating

Plating

-

Post-processing

Post-processing

Home

Home Category

Category Search

Search PTSC

PTSC

KOR

KOR