WELDING

용접

Guyoung Tech

- information

- Overview

- Key Products

- Facilities

Since establishment in 1989, Guyoung Tech, a

company specializing in automotive parts, has been

supplying automotive engine and transmission

brackets, and chassis parts manufactured under

strict quality assurance system applied to the entire

line-up process from press to welding, electrodeposition, and assembly. For the stamping process,

in particular, Guyoung Tech is equipped with

unrivalled technological and price competitiveness

as it has secured internal progressive mold design

and manufacturing capacity. With a goal to become

the world’s leading automotive parts maker and

supplier at reasonable prices through technological

development, quality assurance, and functionality

improvement, Guyoung Tech, a young company

aiming to develop into an advanced enterprise, is

preparing for the multinational competition era

based on progressive and logical thinking

[information]

- Address

- 119, Gukgasandan-daero 39-gil, Guji-myeon, Dalseong-gun, Daegu Metropolitan City, Korea

- Tel

- +82-53-592-6111

- Fax

- +82-53-592-6564

- Website

- http://www.guyoungtech.com/

Products

Automobile seat parts, chassis parts, drive parts, accumulator

Certifications

AEC, ISO14001, IATF16949, OHSAS18001, Hyundai - Kia Motors Quality 5 Stars

Production Facilities

Press, blank, automatic robot line, CO2 welding machine, E-coating facility, hinge assembly equipment, and roller arm assembly equipment, etc.

[History]

- 1986 Migwang Industry established

- 1989 Guyoung Co., Ltd. established

- 1993 Selected as automotive plant for pilot operation (Korea SMEs and Startups Agency)

- 2001 Changed company name to Guyoung Tech

- 2002 Listed stocks in KOSDAQ

- 2003 Obtained ISO/TS 16949

- 2004 Established branch in China

- 2005 Won Gyeongsangbuk-do Industrial Peace Award

- 2006 Obtained ISO 14001, established branch in the U.S.

- 2012 Won Stone Tower Order of Industrial Service Merit, obtained AEO certification

- 2013 Won 50-million-dollar Tower of Export

- 2014 Won Transparent Accounting Award

- 2015 Selected as World Start Company by Daegu Metropolitan City

- 2017 Completed integrated plant at Daegu National Industrial Complex

- 2021 Won Presidential Citation on Taxpayers’ Day Obtained Hyundai-Kia Motors Quality 5 Stars certification

- information

- Overview

- Key Products

- Facilities

[Business Overview and Key Products]

Guyoung Tech is striving to provide competitive products to the global market by establishing automated systems for

medium and large-scale equipment and introducing robot tandem line and equipment shuttle transfer lines to achieve

successful product supply, quality improvement, and cost reduction.

The company’s key products are automotive parts including seat frame for SUVs and premium and large vehicles, oil fan

applied to automotive engines, control arm, which is a strategic export item, and TM bracket.

Producing accumulator, a hydraulic system for heavy equipment, automobiles, agricultural machinery, and ships, based

on the independently developed technology as the first in Korea, Guyoung Tech has expanded the scope of its business.

As a company specializing in the manufacturing of diaphragm, piston, and bladder-type accumulators, Guyoung Tech

supplies products to leading automakers, construction equipment makers, and agricultural machinery makers in Korea

and abroad.

[Features and Strengths]

Realizing global management by establishing overseas production and marketing system

- Production plant measuring approx. 80,000m2 in Alabama, U.S. serving as a bridgehead for export to the U.S, supplying

parts to global automakers

- Enhancing status as a global enterprise by establishing plant with large-scale press, welding system for pipe manufacturing,

cutting, and bending line, and surface treatment line in Weihai of Shandong, China

- information

- Overview

- Key Products

- Facilities

[Key Products]

-

Seat Parts

Seat Parts

-

Chassis Parts

Chassis Parts

-

Drive Parts

Drive Parts

-

Accumulator

Accumulator

- information

- Overview

- Key Products

- Facilities

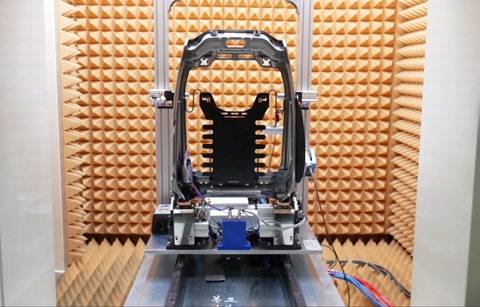

[Production Facilities]

-

Press

Press

-

Automatic Robot Line

Automatic Robot Line

-

Welding Facility

Welding Facility

-

Coating Facility

Coating Facility

-

Door Hinge Opening/Closing Tester

Door Hinge Opening/Closing Tester

-

Seat Tester

Seat Tester

Home

Home Category

Category Search

Search PTSC

PTSC

KOR

KOR