WELDING

용접

Hana Machine

- information

- Overview

- Key Products

- Facilities

Since establishment in 2003, Hana Machine has

been manufacturing industrial mechanical parts

and applying them to chemical and oil refinery

industries to improve abrasion resistance of

facilities. Having recently entered into an MOU

with Technogenia of France, a company that

developed tungsten particles of the highest

hardness as the first in the world and obtained

patent for the technology, Hana Machine

is continuously researching and developing

hard facing technologies using high-hardness

abrasion resistance materials supplied by

Technogenia. The company is committed to

impressing customers under the goal to provide

the highest-quality products

[information]

- Address

- #401, Bando Officetel, 6, Jungheungro 125-beongil, Buk-gu, Pohang-si, Gyeongsangbuk-do, Korea

- Fax

- Website

- http://www.hanamachine.com/

Products

Industrial mechanical part hard facing

Certifications

ISO 9001, Excellent Technology Company, Root Technology Specialist

Production Facilities

Hard facing automation facility, auxiliary facilities for hard facing, welding machines, part processing machinery

[History]

- 2003 Hana Machine established

- 2004 Obtained registration as POSCO processing item

- 2007 Registered in POSCO metal bearing sourcing group

- 2016 Registered in POSCO chemical hard facing sourcing group

- 2017 Hana Machine Co., Ltd. established

- 2018 Entered into agency agreement with Technogenia of France Held hard facing technology seminar (POSCO)

- 2019 Registered in POSCO sourcing group

- 2020 Designated as Root Technology Specialist

- information

- Overview

- Key Products

- Facilities

[Business Overview and Key Products]

- Promoting to improve facility strength by applying high-quality materials and technologies to steel, cement, and other

fields requiring abrasion resistance

1) Industrial mechanical part manufacturing and hard facing

- Ultra-hardness Hard Facing: Most effective for sliding friction resistance

- High-temperature, Impact-resistant, and Abrasion-resistant Hard Facing: Development for POSCO completed

2) Industrial Mechanical Parts: Pumps, mechanical seals, metal bearings

[Features and Strengths]

- Development and Application of Ultra-hardness Hard Facing Materials: Applied to POSCO facilities requiring ultra abrasion

resistance, average lifespan expended from 3 - 6 months to 36 months

- Hard facing materials and application specifications for high temperature (1,000C° or more), impact resistance, and

abrasion resistance

- Technology and specifications for regeneration of cracked areas in casting items at high temperature (800C°or more) (no

PWHT)

- information

- Overview

- Key Products

- Facilities

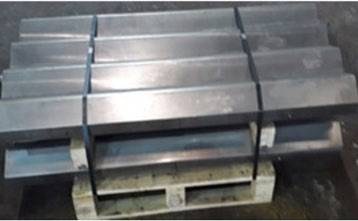

[Key Products]

-

High-hardness Special Alloy Hard Facing

High-hardness Special Alloy Hard Facing

-

High-hardness Special Alloy Hard Facing

High-hardness Special Alloy Hard Facing

-

Medium-hardness Special Alloy Hard Facing

Medium-hardness Special Alloy Hard Facing

-

Medium-hardness Special Alloy Hard Facing

Medium-hardness Special Alloy Hard Facing

-

Medium-hardness Special Alloy Hard Facing

Medium-hardness Special Alloy Hard Facing

-

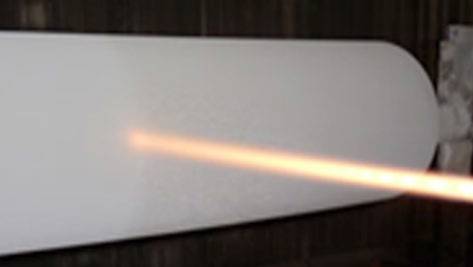

Oxyacetelne Gas Welding Parts

Oxyacetelne Gas Welding Parts

-

Oxyacetelne Gas Welding Parts

Oxyacetelne Gas Welding Parts

-

Oxyacetelne Gas Welding Parts

Oxyacetelne Gas Welding Parts

-

Oxyacetelne Gas Welding Parts

Oxyacetelne Gas Welding Parts

- information

- Overview

- Key Products

- Facilities

[Production Facilities]

-

Technodur-Technosphere

Technodur-Technosphere

-

WC Hardfacing

WC Hardfacing

-

Roll Face WC H.F-Robot

Roll Face WC H.F-Robot

-

Welding Electrodes & Wires

Welding Electrodes & Wires

Home

Home Category

Category Search

Search PTSC

PTSC

KOR

KOR