WELDING

용접

Daeseong

- information

- Overview

- Key Products

- Facilities

Established in Yangsan, Gyeongsangnam-do in

1968, Daeseong started out by producing and

delivering Cortina and truck parts to Hyundai

Motor Group. The company has established

itself as Hyundai Motor Group’s primary

partner based on expertise and technological

power built over 52 years. Having continuously

improved production process and established

advanced production facilities with a goal to

achieve zero defect, Daeseong is currently

designing and mass producing chassis parts for

eco-friendly and latest vehicle models.

[information]

- Address

- Head Office: 53, Daedong-ro, Yangsan-si, Gyeongsangnam-do, Korea

- Tel

- +82-55-372-2007

- Fax

Products

Automotive chassis parts

Certifications

KS A, ISO 22301, IATF 16949, INNOBIZ, Parts and Materials Specialist, KITECH Partner

Production Facilities

1500, 1250, and 800-ton press, assembly tools and spot welding machine, transport robot, CMM 3D measuring system, 3D scanner

[History]

- 1968 Daeseong established

- 1986 Daeseong Precision Co., Ltd. and Daeseong Co., Ltd. Established (changed to corporation)

- 1990 Opened Sangbuk Plant (branch) of Daeseong

- 2001 Opened Yangsan head office of Daeseong, relocated Daeseong Precision head office

- 2002 Obtained QS-9000, opened affiliated research center

- 2012 Won Iron Order of Industrial Service Merit

- 2019 Commenced production of AE EV and FE parts

- 2020 Obtained Root Technology Specialist and Parts and Materials Specialist Certifications

- 2021 Commenced parts for latest automotive models including US4 (Staria)

- information

- Overview

- Key Products

- Facilities

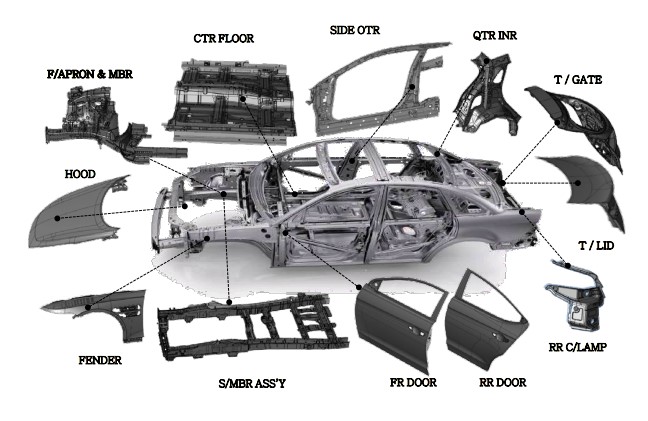

[Business Overview and Key Products]

- Automotive chassis parts

· Most parts applied to BIW, such as CTR floor, side OTR, quarter inner, rear combination lamp, fender apron & member,

trunk lid, tailgate, hood, and FR/RR door

- Equipped with separate mold plant for internal mold and product manufacturing

[Features and Strengths]

- Producing chassis parts for most vehicle models manufactured at Ulsan Plant of Hyundai Motor Group, a key customer

- information

- Overview

- Key Products

- Facilities

[Key Products]

-

Key Products

Key Products

- information

- Overview

- Key Products

- Facilities

[Production Facilities]

-

1500-ton Press Line

1500-ton Press Line

-

800-ton Press Line

800-ton Press Line

-

1500-ton Robot

1500-ton Robot

-

3D Measuring System

3D Measuring System

-

Tensile Strength Tester

Tensile Strength Tester

Home

Home Category

Category Search

Search PTSC

PTSC

KOR

KOR