METAL FORMING

소성가공

Samjin

- information

- Overview

- Key Products

- Facilities

With a goal to achieve near-finish size of plastic

products, Samjin predicts and prevents forging

defects, which can occur inside products, at

the same time as developing optimal designs

through new forging material development

and finite element analysis for forging process

verification. Many parts that used to be

manufactured through cutting process are now

being produced economically and in uniform

quality through a composite production process

combining cold forging, hot forging, and press

machining.

[information]

- Address

- Cheonan Plant (Head Office): 68, Daeheung 1-gil, Seongnam-myeon, Dongnam-gu, Cheonan-si, Korea

- Tel

- +82-41-410-6000

- Fax

- Website

- http://www.samjinnut.co.kr/

Products

Automotive parts (nut)/cold and hot forging products

Certifications

IATF 16949:2016, ISO 45001:2018, ISO 14001:2015

Production Facilities

1,000-ton multi-stage press, a range of cold and hot formers, approx. 400 tapping machines

[History]

- 1973 Company established

- 1998 Won Presidential Metal (No. 108769)

- 2010 Opened affiliated research center

- 2013 Won Gold Tower Order of Industrial Service Merit (No. 757)

- 2014 Won Automotive parts Industry Award

- 2015 Won 70-million-dollar Tower of Export

- 2016 Won Citation at Labor - Management Culture Awards trademark

- information

- Overview

- Key Products

- Facilities

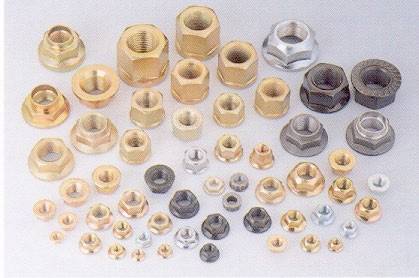

[Business Overview and Key Products]

Equipped with approximately 400 tapping machines along with a range of cold and hot formers as well as a 1,000-ton multistage press, Samjin manufactures forging products and nuts in various shapes and sizes ranging from M3 to M64.

It is capable of manufacturing 300 million products, such as automotive and industrial parts, a month according to customers’

varying needs. Samjin’s key product is automotive nuts, which include not only flange nut, lock nut, and conical nut used

in the assembly process at automobile plants, but also a wide variety of forging products, such as weld nut applied to the

automotive chassis and piston and flare nuts used for engines and brakes. Having obtained the IATF 16949, ISO 14001, and

ISO 45001 certifications, Samjin provides safe and reliable products to customers. The company’s ultimate goal is to achieve

“zero defect.”

[Features and Strengths]

- information

- Overview

- Key Products

- Facilities

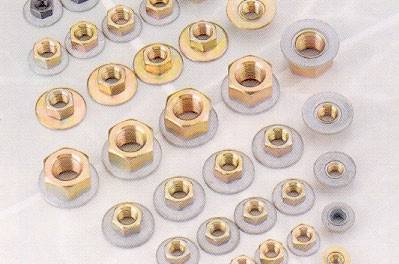

[Key Products]

-

HEX Nut

HEX Nut

-

Conical nut

Conical nut

-

Weld nut

Weld nut

-

Wheel nut

Wheel nut

-

Flange nut

Flange nut

-

Lock nut

Lock nut

-

Slotted & Castle

Slotted & Castle

-

Nylon lock

Nylon lock

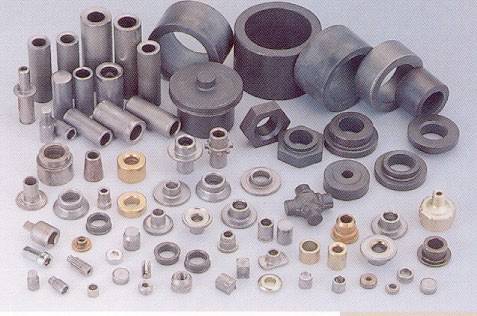

-

Con-rod nut

Con-rod nut

-

Piston pin

Piston pin

-

Female parts

Female parts

- information

- Overview

- Key Products

- Facilities

[Production Facilities]

-

Rockwell Hardness Tester

Rockwell Hardness Tester

-

U.T.M

U.T.M

-

Chemical Composition Analyzing System

Chemical Composition Analyzing System

-

Forming Machine

Forming Machine

-

Tapping Machine

Tapping Machine

-

Press

Press

-

Testing and Packaging Facilities

Testing and Packaging Facilities

-

Testing and Packaging Facilities

Testing and Packaging Facilities

Home

Home Category

Category Search

Search PTSC

PTSC

KOR

KOR