CASTING

주조

Delta Cast

- information

- Overview

- Key Products

- Facilities

Leading aluminum gravity casting with

technological power built over 30 years,

Delta Cast has been dedicating efforts to

becoming a company of the highest quality

in aluminum automotive part casting field.

Under the fundamental philosophy to place the

highest priority on quality by achieving zero

defect through systematized organizational

management and production line operation,

Delta Cast is committed to achieving the

highest quality in gravity casting and processing

for aluminum automotive casting parts and

materials.

[information]

- Address

- 59, Nongong-ro 91-gil, Nongong-eup, Dalseong-gun, Daegu Metropolitan City, Korea

- Tel

- +82-53-615-9621

- Fax

- +82-53-615-9300

- Website

- http://www.deltacast.co.kr/

Products

Automotive parts and materials, marine engine parts, parts for wind power generation, vacuum chamber for semiconductor process, and parts for robot, etc.

Certifications

IATF16949-2016, Hyundai Motor Company - Kia Motors SQ Mark

Production Facilities

Gravity casting machine (45 sets), molten metal degassing machine (9 sets), heat treatment furnace

[History]

- 1984 Namsun Industries established (Namsun Aluminum)

- 1990 Registered as partner for KDAC/KASCO

- 2005 Delta Cast established (Parent Company: Wooshin Metal) (acquired Namsun Industries)

- 2006 Won ISO/TS16949 certification and Hyundai Motor Company - Kia Motors SQ Mark

- 2016 Designated as Employment-friendly Company by Daegu Metropolitan City

- 2017 Completed Delta Cast Daehap Plant (in Changnyeong Daehap Industrial Complex)

- information

- Overview

- Key Products

- Facilities

[Business Overview and Key Products]

- Automotive Brake Parts: Automobile power brake master cylinder, caliper, mono-caliper, wheel cylinder

- Automotive Engine Parts, Axle Parts: EGR valve housing, air brake compressor housing, axle-diff carrier

[Features and Strengths]

Gravity casting production capacity by 600 tons a month

- information

- Overview

- Key Products

- Facilities

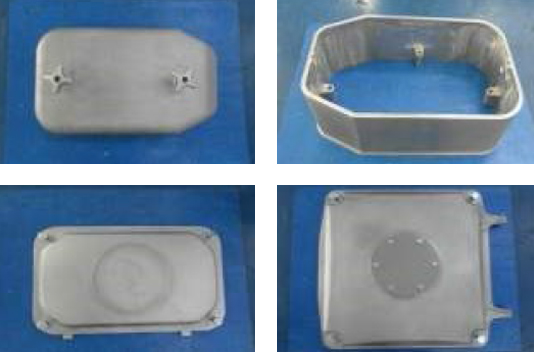

[Key Products]

-

Automotive Brake Parts

Automotive Brake Parts

-

Automotive Engine Parts, Axle Parts

Automotive Engine Parts, Axle Parts

-

Marine Engine Parts

Marine Engine Parts

-

Wind Power Generation Parts

Wind Power Generation Parts

- information

- Overview

- Key Products

- Facilities

[Production Facilities]

-

Gravity Casting Machine

Gravity Casting Machine

-

Molten Metal Degassing Machine

Molten Metal Degassing Machine

-

Heat Treatment Furnace

Heat Treatment Furnace

-

Spectrometer

Spectrometer

-

CT Equipment

CT Equipment

-

3D Measuring Machine

3D Measuring Machine

Home

Home Category

Category Search

Search PTSC

PTSC

KOR

KOR