WELDING

용접

LASERVALL Technology

- information

- Overview

- Key Products

- Facilities

Recording the largest share in laser jet

soldering market by supplying products to

global enterprises, such as Samsung, Apple, LG,

Huawei, and Foxconn, LASERVALL Technology is

equipped with unrivalled technological power

and expertise in the fields of not only laser

jet soldering, but also laser cutting, marking,

and welding. Having established a global

network comprising of overseas branches

in China, Vietnam, India, and Singapore, the

company is promoting to become an “integrated

solution provider” in order to increase sales to

approximately USD 100 million

[information]

- Address

- 86-10, Banwolnam-gil, Hwaseong-si, Gyeonggi-do, Korea

- Tel

- +82-70-8861-7052

- Fax

- Website

- http://www.microsoldering.co.kr/

Products

Laser soldering, cutting, marking, and welding-related technology development

Certifications

Venture Company, Parts and Materials Specialist, ISO 9001, Root Technology Specialist

Production Facilities

Laser soldering machine, laser cutting machine, laser marking machine

[History]

- 2003 Company established (Hong Kong)

- 2007 Established branch and plant in China

- 2010 Established branch in India

- 2013 Released fiber laser source, “Filos”

- 2014 Released advanced laser jet soldering system Developed 3D laser marking system

- 2015 Established branch in Vietnam

- 2018 Converted to corporation in Korea

- 2019 Opened affiliated research center Opened office in Singapore

- 2020 Designated as Root Technology Specialist

- information

- Overview

- Key Products

- Facilities

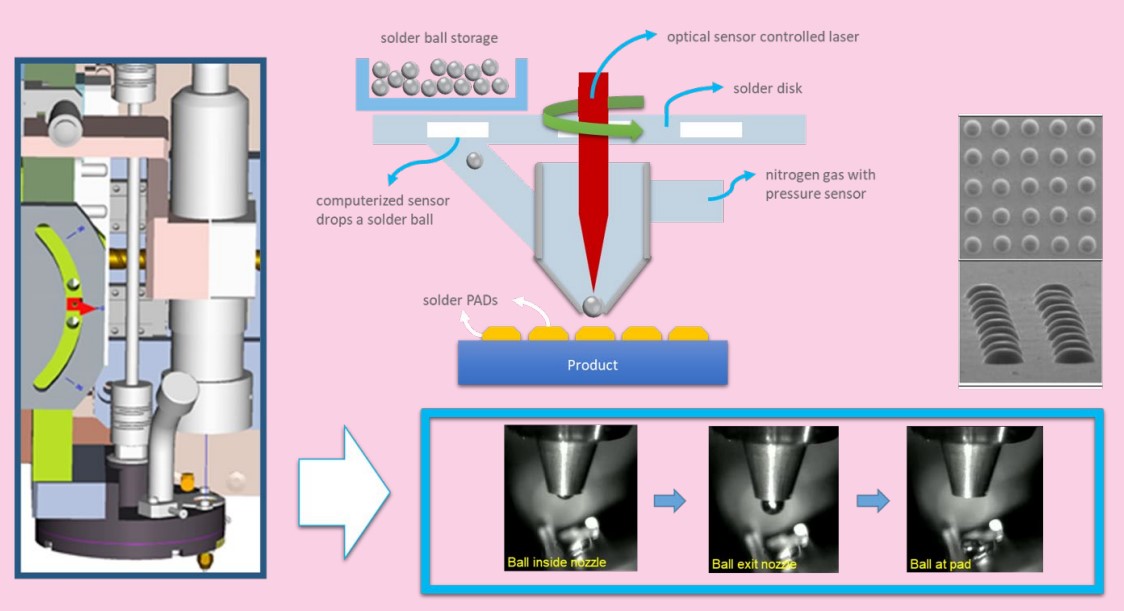

[Business Overview and Key Products]

- A variety of soldering technologies are available, such as hot bar, hot plate, resistance, iron, torch, tip, and laser types.

However, there is a need for micro-soldering process system of high accuracy comprising of compact camera module, AFA

(auto focus actuator), and OIS (optical image stabilizer).

- In line with the market demand, LASERVALL Technology has developed laser jet soldering technology and is providing the

related solutions. It also provides the laser-related application solutions based on understanding of laser and automation

facilities.

[Features and Strengths]

- For the next-generation micro-soldering process, laser jet soldering solution, which

improved on the weaknesses of the existing flux-based laser wire equipment and enables

high-speed, high-precision, and flexible processing and clean working environment, is

being widely applied.

- information

- Overview

- Key Products

- Facilities

[Key Products]

-

Micro Laser Solder(MLS) System

Micro Laser Solder(MLS) System

-

Plastic Welding System

Plastic Welding System

-

LCS-Cutting System

LCS-Cutting System

-

PCB Marking System

PCB Marking System

- information

- Overview

- Key Products

- Facilities

[Production Facilities]

-

Production Process

Production Process

Home

Home Category

Category Search

Search PTSC

PTSC

KOR

KOR