WELDING

용접

DYNAMO TECH

- information

- Overview

- Key Products

- Facilities

Based on the technological power accumulated

through PBC assembly production over 30 years

since establishment in 1993, DYNAMO TECH

strives to meet all customer needs, improve

product quality, and enhance productivity. While

leading Korea’s SMT industry, the company is

promoting to achieve zero defect rate under

the management policy to “stabilize quality to

strengthen competitiveness.” With the advanced

SMT facilities and strict quality control, DYNAMO

TECH is positioning itself as the industry leader.

[information]

- Address

- 57, Juyeop-ro, Michuhol-gu, Incheon Metropolitan City, Korea

- Tel

- +82-31-872-3444

- Fax

- +82-32-872-3443

Products

Cosmetic equipment/sensor/mobile/medical instrument PCB, automobile PCB assembly

Certifications

SQ Mark, IATF-16949, Root Technology Specialist, INNOBIZ

Production Facilities

Mounting equipment, nitrogen generator, screen printer, automatic cleaning machine, solder agitator

[History]

- 1993 Hyeonseok Electronics established

- 1999 Changed trade name to Shingwang SMT Electronics

- 2006 Relocated Juan Plant and extended SMT line

- 2007 Obtained SQ Mark (Grade A)

- 2008 DYNAMO TECH Co., Ltd. established

- 2019 Changed trade name to DYNAMO

- 2020 Obtained approval for defense industry special process and designation as service provider for Hanwha Obtained Root Technology Specialist certification

- 2021 Obtained INNOBIZ certification (Grade A) terminal

- information

- Overview

- Key Products

- Facilities

[Business Overview and Key Products]

1) SMT: Operating a number of Yamaha SMT machines of the highest specifications

2) Assembly: Producing cosmetic equipment/sensor/mobile/medical instrument/automobile PCB assembly with the goal of zero defect rate

[Features and Strengths]

- Equipped with erroneous insertion prevention system and product reliability improvement system to achieve zero defect rate

- information

- Overview

- Key Products

- Facilities

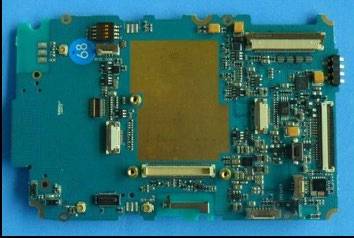

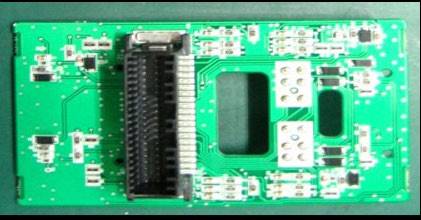

[Key Products]

-

Magic Dry PCB Ass’y

Magic Dry PCB Ass’y

-

Magic Dry PCB Ass’y

Magic Dry PCB Ass’y

-

M3 Mobile PDA and PCB Ass’y

M3 Mobile PDA and PCB Ass’y

-

M3 Mobile PDA and PCB Ass’y

M3 Mobile PDA and PCB Ass’y

-

PCB Ass’y for Medical Instruments

PCB Ass’y for Medical Instruments

-

PCB Ass’y for Medical Instruments

PCB Ass’y for Medical Instruments

-

Nissan PCB Ass’y

Nissan PCB Ass’y

-

Nissan PCB Ass’y

Nissan PCB Ass’y

-

JF Console PCB Ass’y

JF Console PCB Ass’y

-

Jack Ass’y Assembly

Jack Ass’y Assembly

- information

- Overview

- Key Products

- Facilities

[Production Facilities]

-

Mounting Equipment

Mounting Equipment

-

Mounting Equipment

Mounting Equipment

-

Screen Printer

Screen Printer

-

Reflow

Reflow

Home

Home Category

Category Search

Search PTSC

PTSC

KOR

KOR