WELDING

용접

DK AUSTECH

- information

- Overview

- Key Products

- Facilities

Since establishment in 1963, DK AUSTECH has been

specializing in the manufacturing of suspension

parts, which are most important for automobile

driving, safety, and durability performances, as

well as various other automotive parts. In addition

to the collective production system comprising of

press, welding, mechanical processing, assembly,

and coating processes, DK AUSTECH has introduced

automated and foolproof equipment to entire

processes, and thus established an independent

and innovative quality assurance system. DK

AUSTECH is leading automotive part production

in the 21st century by striving to secure cost

competitiveness for customer satisfaction based on

plant efficiency maximization through continuous

VE and IE activities.

[information]

- Address

- Head Office : 23, Nonggong-gil, Jeonggwaneup, Gijang-gun, Busan Metropolitan City, Korea

- Tel

- +82-51-727-7071

- Fax

- Website

- http://www.dkaustech.com/

Products

Automotive parts

Certifications

ISO 9002, QS 9000, ISO/TS 16949, ISO 14001, IATF 16949

Production Facilities

Stamping 800T line, welding line (CO2, spot, T.W.B.), cation painting line

[History]

- 1963 Ildong Electric Co., Ltd. established

- 1995 Registered as part supplier of Samsung Motors Concluded technological affiliation with and invested in YOROZU of Japan

- 1996 Opened affiliated research center

- 2006 Changed company name to DK AUSTECH

- 2012 Won 30-million-dollar Tower of Export

- 2013 Delivered products directly to Nissan

- 2016 Won 70-million-dollar Tower of Export Won Presidential Award for Export

- 2017 Won Korea’s Best Trader Award

- 2020 Won 30-million-dollar Tower of Export (Korea International Trade Association) Obtained Root Technology Specialist and MAINBiz certifications Relocated head office and Noksan Plant

- information

- Overview

- Key Products

- Facilities

[Business Overview and Key Products]

- 2014: Focused on the production of rear suspension/front suspension/rear arm parts, added new products for foot

parking brake

- 2016: Localized and started supply of lightweight and high-strength chassis products and tubular beam

- 2017: Completed localization of rear axle for SM3 electric vehicles, entered electric vehicle market Received orders for UJL

project (XM3) and HJB for new vehicle models of Renault Samsung Motors

[Features and Strengths]

- information

- Overview

- Key Products

- Facilities

[Key Products]

-

Front Suspension

Front Suspension

-

Rear Suspension

Rear Suspension

-

Link Parts

Link Parts

-

Link Parts

Link Parts

-

Break Parts, etc.

Break Parts, etc.

-

Break Parts, etc.

Break Parts, etc.

-

Break Parts, etc.

Break Parts, etc.

- information

- Overview

- Key Products

- Facilities

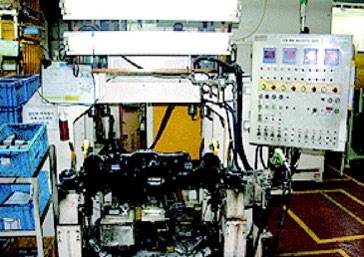

[Production Facilities]

-

Stamping

Stamping

-

Welding

Welding

-

Painting

Painting

-

Assembly

Assembly

Home

Home Category

Category Search

Search PTSC

PTSC

KOR

KOR