METAL FORMING

소성가공

Samsungtech

- information

- Overview

- Key Products

- Facilities

Since establishment in 1977, Samsungtech

has advanced to a company with the highest

technological power in Korea and global

competitiveness by focusing on press mold and

processing fields according to the company’s

motto to achieve customer satisfaction and

contribute to national industrial development.

Under the management philosophy that

“customers come first,” Samsungtech is

conducting continuous R&D of and investment

in various press processing items raging from

automobile and aircraft to medical equipment

precision parts. Samsungtech is preparing to

take the leap into a global enterprise that leads

the drawing processing industry.

[information]

- Address

- 67, Geumbak-ro 133-gil, Jinnyang-eup, Gyeongsan-si, Gyeongsangbuk-do, Korea

- Tel

- +82-53-857-0300

- Fax

- +82-53-857-9564

- Website

- http://www.samsungtech.kr/

Products

Automobile parts

Certifications

ISO 14001, IATF 16949, INNOBIZ, Parts and Materials Specialist, MAINBiz, SQ, Gyeongsangbuk-do Pride Product Maker

Production Facilities

NC leveler feeder, blanking press, auto robot line

[History]

- 1977 Samsung Industries established (Daegu)

- 1986 Relocated to Seongseo Industrial Complex

- 2008 Integrated with Samsungtech (Jinnyang Plant)

- 2013 Opened affiliated research center Established 1300 and 1000-ton press robot automation line

- 2014 Won Gyeongsangbuk-do SME Award Introduced KOSHA 18001 Safety and Health Management System

- 2015 Selected as one of 100 Enterprises of Gyeongsangbuk-do Techno Park

- 2020 Designated as Root Technology Specialist

- 2021 Designated as Promising Export Small Enterprise by Ministry of SMEs and Startups Designated as Talent Fostering Small Enterprise by Korea SMEs and Startups Agency

- information

- Overview

- Key Products

- Facilities

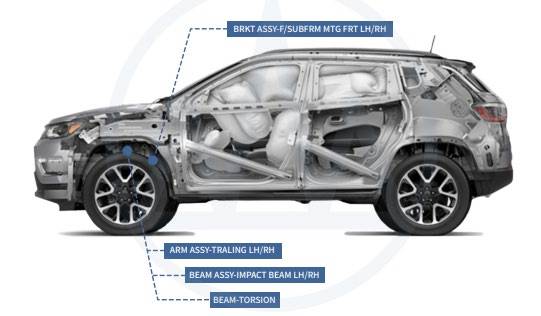

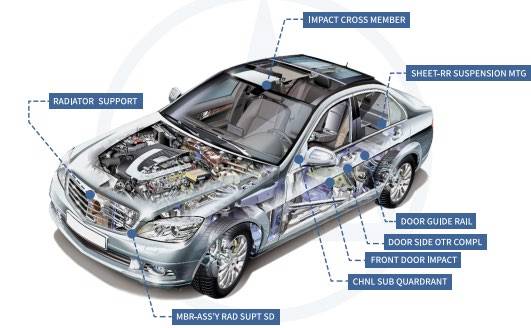

[Business Overview and Key Products]

Focusing on the production of automobile chassis and body parts

[Features and Strengths]

- Developing new products, technologies, and business items to lead future growth centering on the affiliated research center Supporting R&D of process facilities, welding technologies, and smart factory technologies to achieve productivity and quality improvement Promoting automated production system by operating Yaskawa Motoman robot, the company’s main robot, together with other facilities

- information

- Overview

- Key Products

- Facilities

[Key Products]

-

Chassis Parts

Chassis Parts

-

Body Parts

Body Parts

- information

- Overview

- Key Products

- Facilities

[Production Facilities]

-

NC Leveler Feeder

NC Leveler Feeder

-

Blanking Press

Blanking Press

-

Auto Robot Line

Auto Robot Line

-

Auto Robot Line

Auto Robot Line

-

Auto Robot Line

Auto Robot Line

Home

Home Category

Category Search

Search PTSC

PTSC

KOR

KOR