METAL FORMING

소성가공

Sewon Advanced Metals

- information

- Overview

- Key Products

- Facilities

Established in 2002, Sewon Advanced

Metals specializes in the development and

manufacturing of highly functional copper

alloy products. Using high-quality ingots, the

company not only processes copper bus bars

and bus bars of various specifications, but also

manufactures copper, brass, phosphor bronze,

and zinc plate products. Under the company

motto to “dedicate the utmost effort based on

sincerity,” Sewon Advanced Metals is striving

to achieve customer satisfaction with the topquality products and swift delivery.

[information]

- Address

- Head Office : #4, Block 602, 120, Neunggil-ro, Danwon-gu, Ansan-si, Gyeonggi-do, Korea

- Tel

- +82-31-495-0107

- Fax

- +82-31-495-6651

- Website

- http://www.sewon.wonilsa.co.k/

Products

Copper bus bar, bus bar, coil, copper plate, brass plate

Certifications

ISO 9001, ISO 14001, INNOBIZ, MAINBiz, Venture Company

Production Facilities

[History]

- 2002 Sewon Advanced Metals established

- 2005 Obtained permit to display KS Mark (phosphor bronze and nickel silver plate and coil)

- 2007 Built Yeoncheon Plant 2 and relocated it to Pocheon Obtained Clean Business Establishment certification

- 2009 Installed rotary furnace (commenced bus bar billet internal production)

- 2012 Opened technology research center Selected as Ideal Workplace for Employment

- 2014 Conducted energy technology development project

- 2017 Selected as Root Technology Specialist

- information

- Overview

- Key Products

- Facilities

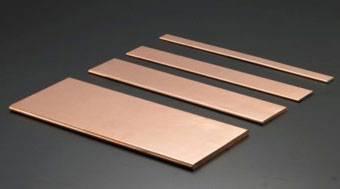

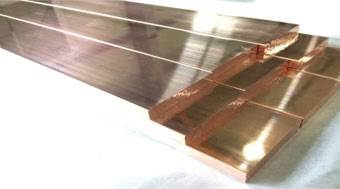

[Business Overview and Key Products]

- Copper Bus Bar: Part for switch, circuit breaker, distribution board, and large-capacity wiring instruments, producing

effect to reduce power loss

- Tough Pitch Cooper: Electrical parts, such as gasket, connector, and transformer coil, characterized with high electrical

conductivity and excellent physical properties

- Phosphorus Deoxidized Copper: Oxygen content 100ppm or less, applied to building facilities, heat exchanger, and

welding facilities

- Oxygen-free Copper: High-grade pure copper with copper content of 99.96% or higher, applied to electrical/electronic

products, such as compression terminal, magnetron, and vacuum tube

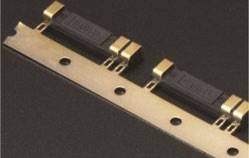

- Brass Parts: Copper and zinc alloy, applied to light bulb socket, antenna, musical instruments, and kitchen appliances

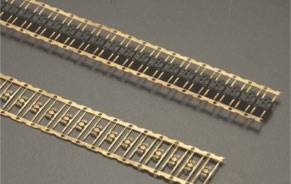

- Phosphor Bronze: Copper and tin alloy with a small amount of phosphorous added, used as material for connector,

brush, and premium spring, etc.

[Features and Strengths]

- Copper bus bar processing : Process to cut, perforate, bend, plate, and insulate bus bar, implemented according to customer needs

- information

- Overview

- Key Products

- Facilities

[Key Products]

-

Copper Bus Bar

Copper Bus Bar

-

Copper Bus Bar

Copper Bus Bar

-

Tough Pitch Coppe

Tough Pitch Coppe

-

Tough Pitch Coppe

Tough Pitch Coppe

-

Phosphorous Deoxidized Copper

Phosphorous Deoxidized Copper

-

Oxygen-free Copper

Oxygen-free Copper

-

Oxygen-free Copper

Oxygen-free Copper

-

Brass Parts

Brass Parts

-

Brass Parts

Brass Parts

-

Phosphor Bronze

Phosphor Bronze

-

Phosphor Bronze

Phosphor Bronze

- information

- Overview

- Key Products

- Facilities

[Production Facilities]

-

Melting/Refining

Melting/Refining

-

Casting

Casting

-

Extrusion

Extrusion

-

Pointing

Pointing

-

Correction

Correction

-

Cutting

Cutting

Home

Home Category

Category Search

Search PTSC

PTSC

KOR

KOR