HEAT TREATIMENT

열처리

ThermVac

- information

- Overview

- Key Products

- Facilities

Following conversion to manufacturing business in

2000, ThermVac obtained the basic vacuum furnacerelated technologies, and has since been focusing

solely on the development of vacuum furnace

equipment by working on technology development

projects of the Ministry of SMEs and Startups and

the Ministry of Trade, Industry and Energy. As a

result, the company succeeded in developing and

commercializing equipment that had previously been

monopolized by advanced countries, such as ceramic

CVD equipment, high-pressure gas cooling vacuum

furnace system, ultra high temperature graphitizing

furnace, and super graphitizing furnace. While

supplying a range of high-performance vacuum

furnace equipment and systems, which are required

for the manufacturing of new materials and parts,

ThermaVac is exporting value-added large vacuum

furnaces to China and Japan.

[information]

- Address

- 480-126, Jangan-ro, Jangan-myeon, Hwaseong-si, Gyeonggi-do, Korea

- Tel

- +82-31-351-4490

- Fax

- Website

- http://www.thermvac.co.kr/

Products

Vacuum furnace, pressing furnace

Certifications

INNOBIZ, Venture Business Certification, MAINBiz, Smart Plant Certification

Production Facilities

Super graphitizing furnace, quenching vacuum furnace, ceramic CVD

[History]

- 2005 Established affiliated research center

- 2007 Entered Japanese market

- 2012 Developed ceramic CVD equipment

- 2017 Entered Chinese market

- 2018 Developed gas pressure cooling vacuum furnace

- 2019 Developed carbon super graphitizing furnace

- 2020 Entered German market

- information

- Overview

- Key Products

- Facilities

[Business Overview and Key Products]

Focusing on development and supply of equipment specialized to processes in extreme conditions, such as ultra high

temperature hot working process at 2000°C or higher, gas environment process using chlorine and hydrogen, etc, highpressure process using axial pressure or gas pressure, and ultra high vacuum process at approx. 10 (-7) torr, on vacuum

furnace platform essential for new material and part development or production

[Features and Strengths]

Pressure Vessel Design/Manufacturing Technology: Certified by Korea Occupational Safety and Health Agency (KOSHA) and

Korea Gas Corporation (KOGAS)

2) Thermal Flow Analysis: Heat transfer and conduction analysis, hot working gas flow analysis

3) High Temperature Process Development Technology: Ceramic/carbon chemical vapor deposition process (CVD/CVI), super

graphitizing process (chlorine, fluorine environment)

4) Composite Heat Treatment Process Control Technology: Ultra high temperature increase control, rapid cooling control, gas

tension control, pressurization contro

- information

- Overview

- Key Products

- Facilities

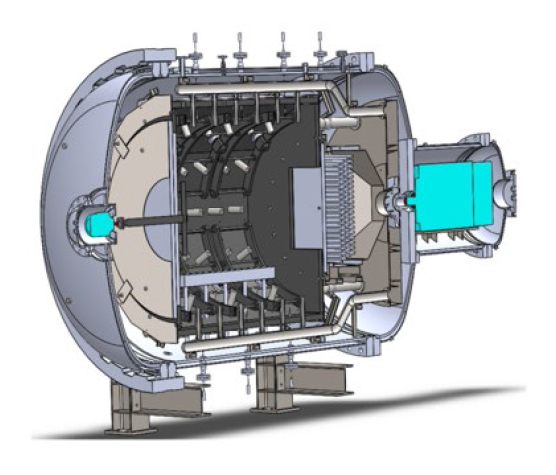

[Key Products]

-

Gas Pressure Heating/Cooling Process

Gas Pressure Heating/Cooling Process

-

Ultra High Temperature Firing Process

Ultra High Temperature Firing Process

-

CVD/CVI Thin Film Deposition Process

CVD/CVI Thin Film Deposition Process

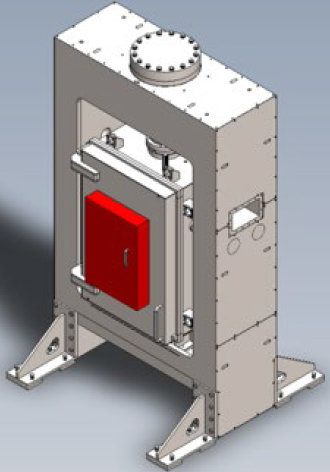

-

Pressurized Bonding/Sintering Process

Pressurized Bonding/Sintering Process

- information

- Overview

- Key Products

- Facilities

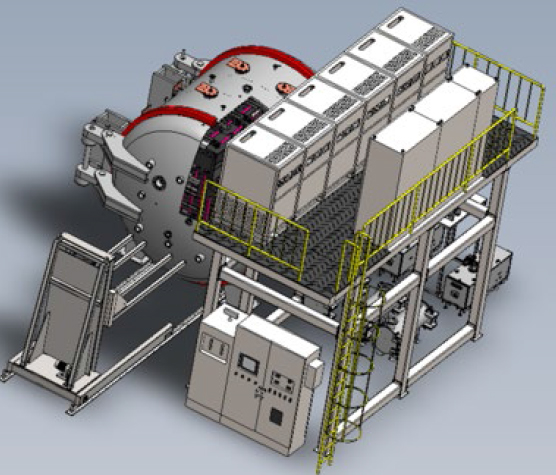

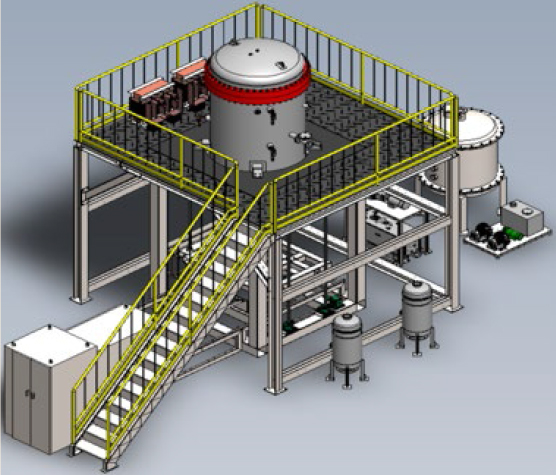

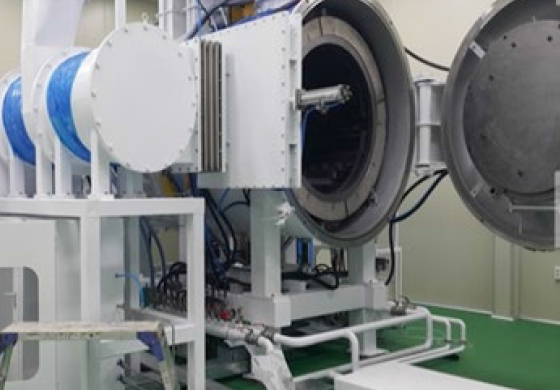

[Production Facilities]

-

Dual-chamber Graphitizing Furnace

Dual-chamber Graphitizing Furnace

-

Gas Pressure Sintering Furnace (GPS)

Gas Pressure Sintering Furnace (GPS)

-

Ultra High Temperature CVD

Ultra High Temperature CVD

-

Dual-chamber Vacuum Heat Treatment Furnace

Dual-chamber Vacuum Heat Treatment Furnace

Home

Home Category

Category Search

Search PTSC

PTSC

KOR

KOR